Monitoring the sound of silence

[Git] [three.js] [Scala] [AngularJS] [Javascript] [Java]

Imagine you have a massive source of untapped information lying at the bottom of the sea, waiting for some bright minds to make use of it. Then, an idea springs into the mind of a developer - and it becomes a reality.

It all started in 2014 when Mats Grønning Andersen entered the CIO Idea Spot competition. The challenge? To find an area where massive amounts of unused data could prove valuable to Equinor. Mats took home the grand prize with his suggestion of using data from seismic cables buried into the sea floor above some of our reservoirs.

Normally, we only use the data from these cables whenever we conduct seismic surveys. But, having previously worked with geophysics and seismic imaging, I knew that there were large amounts of unused data available.

Mats Grønning Andersen

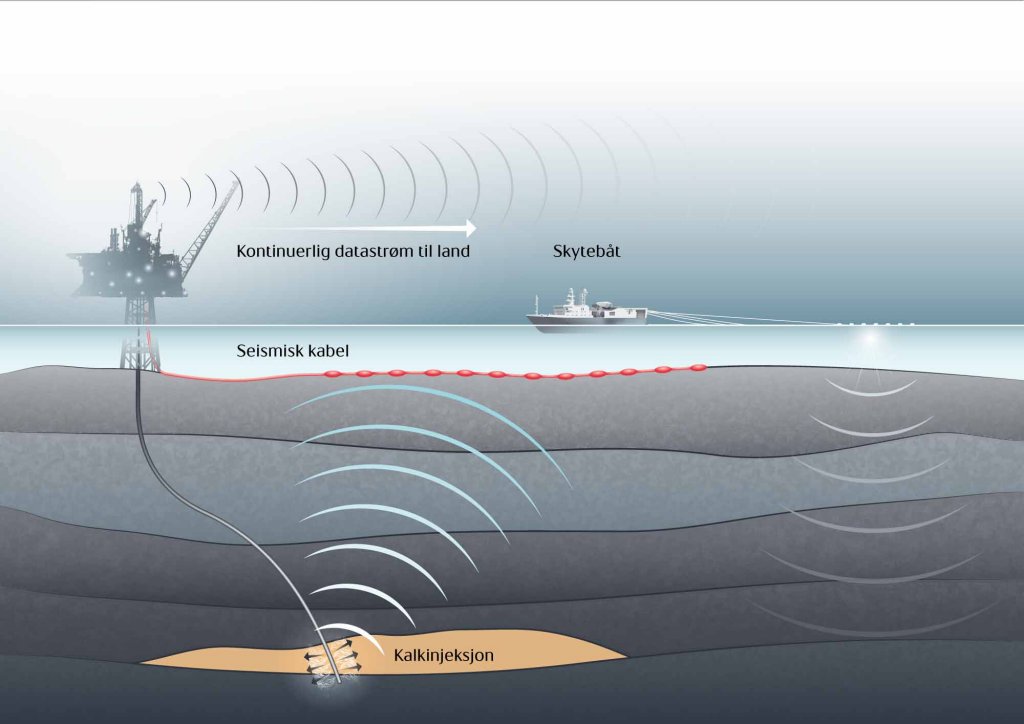

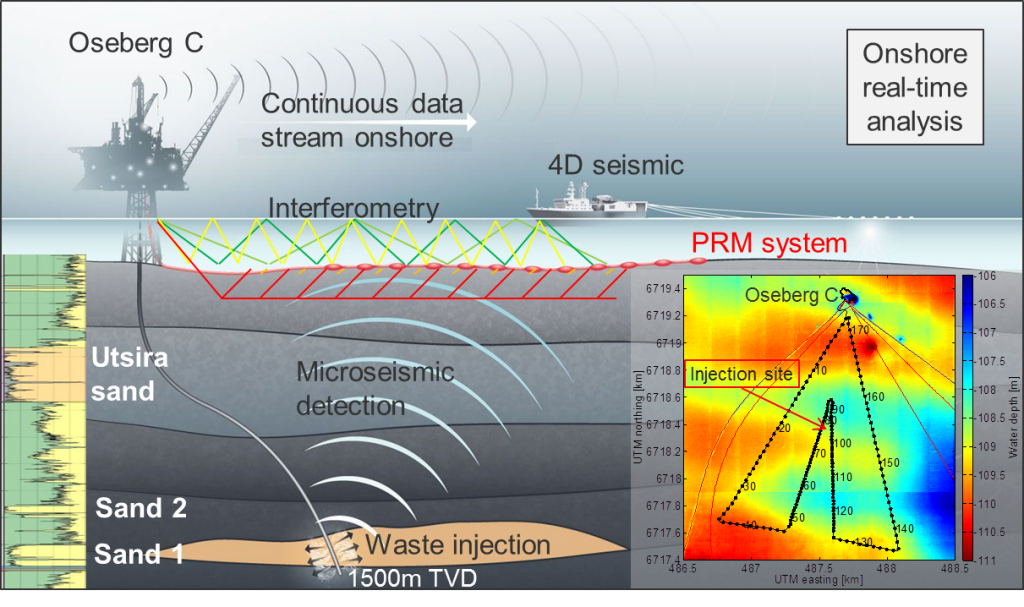

When acquiring seismic data, cables are usually towed behind a boat. This is done regularly to monitor changes in the subsurface. Since it is very difficult to recreate the exact same imagery each time, a permanent reservoir monitoring system can be placed on the seafloor. This makes it easier to get a good (less noisy) picture of the changes caused by production and injection. Some of Equinor’s fields are covered with this type of permanent seismic cables.

Seismic data 101

Equinor and other companies use seismic data to map the subsurface. This is done by sending energy down into the earth (compressed air is used to create sound waves in the sea or with a vehicle on land), and record the echoes that return to the surface. Seismic data can be used to estimate the properties of the subsurface and look for new oil fields or increase the production from existing fields.

“When I submitted my idea, the cables were picking up signals from earthquakes, wave activity and sounds from below ground without us putting them to any use. Now, we can use them to pick up activity related to production and injection,” Mats says.

Injection means the cuttings that are produced when you're drilling a new well, or the surplus water generated when a well is in production. These cuttings and water is often pumped back into the ground.

“The idea is that we create pressure when we pump these fluids into the reservoirs and the pressure can generate cracks in the rocks, which produce sound. Then, microphones can pick up these sounds and we can use it to find the location of the cracks. While these cracks are not harmful and we expect them to occur, we still need to make sure we know where the injected fluid goes. This means we can stop the injection if there is a risk of it reaching the sea floor,” Mats tells us.

Watch this quick introduction to Sentry to learn what it does and how it came to be. (Video: Torstein Lund Eik)

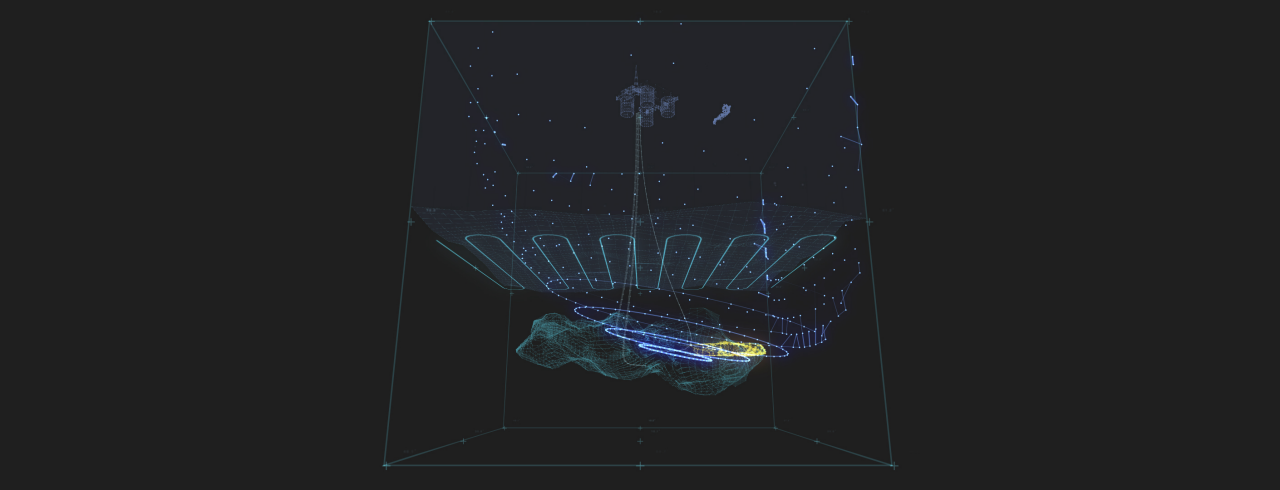

What is Sentry?

A tool to register, analyze and present sounds that occur in or above the reservoir.

- Real-time detection and monitoring using geophones on the seafloor.

- The geophones listen for sound waves created by irregularities.

- Triangulation is used to detect the event location.

- Sentry processes the information in several ways and presents detailed analysis on an always-available website.

An advantage being in IT

Even though the competition was open to anyone within the company, a big part of it was to utilize software to analyze and make use of existing unused data. To no surprise, already working in IT and with software innovation was no disadvantage.

Listen to Mats talking about the benefits of working in Software Innovation. (Video: Torstein Lund Eik)

“The biggest advantage for me was that I didn’t just have an idea of what I wanted to do. I could also suggest solutions and make suggestions on how I wanted to actually solve it. Not to mention that I could build a competent and resourceful team that could help take it from the idea stage to implementation,” Mats tells us.

After submitting his idea he ended up winning the entire competition. Now, the hard work really began. Corporate IT and Equinor Research & Technology funded the work but time was not on Mats’ side.

A project like this would be nearly impossible to pull off alone but luckily he was able to assemble a team of four. Mats was joined by Arve Skogvold, Terje Barstad Olsen and Vidar Slåtten and work could begin. Since none of them had previous experience within geophysics, they had to find someone that could help them.

Mats explains that meeting the right people was crucial for Sentry's development. (Video: Torstein Lund Eik)

They worked together with geophysicists from the Oseberg field, and they were joined by Grane geophysicists later on. Mats calls this cooperation the “holy grail” of research cooperation.

We were able to work together with people from all parts of the operation; from technical staff and researchers to those working with day-to-day operations offshore. It’s a textbook example of proper cooperation and I believe this is why we were able to finish such a large project in just 6 months, Mats says.

Hoping to never detect events

The project was originally named Passive Monitoring (PM) but today it’s known by the catchier name Sentry. It stands guard over the reservoirs and keeps an eye out for irregularities, much like a soldier at its guard post. But in addition to monitoring the tool has also helped boost technology within Equinor.

“The fact that Sentry got as much attention and support that it did has opened the door for a technological evolution. We’ve also seen an increase in the field of seismic interferometry and microseismic events,” Mats says.

“The work being done by Sentry is inspired by work that’s been done by other companies, and the geophysics of it all is well-known from the past 100 years of earthquake readings. But no one has previously seen the potential to use this data in the way we’re doing now.”

Mats Grønning Andersen

One of the talented people Mats found help in is Sascha Bussat, a geophysicist and project leader for SWIM (Seismic Waste Injection Monitoring), who now uses Sentry in his day-to-day operations.

“Sentry came around at the perfect time and helped us in further developing tools for monitoring injection wells. Benchmark tests proved it was working nearly as well as the top-of-the-line contractor tools, which gave us more reason to keep on developing the software,” Bussat explains.

Today, he monitors data and develops and implement new methods to keep on improving Sentry. The program picks up on small events such as cracks and movements, which are difficult to spot using just data.

“While these events are small, it’s very useful for us to see that Sentry detects them. It shows that it’s working properly. For example, cracks in slate will result in larger events and I feel certain that this tool will detect these,” he says.

Highway to the geophone zone

There’s one item still left unmentioned that is quite essential to the entire program - the geophone. These meter-long, almost banana-shaped electronic devices are scattered across the seafloor above two of Equinor's oil reservoirs.

Around 3,500 (yeah, you read that right) of these “bananas” all listen for sounds in the Grane reservoir. Since we're already talking big numbers it's worth mentioning that on the Snorre field alone more than 10 000 geophones are installed.

Richard Tøndel is the project leader of Real Time Injection Monitoring and explains how these geophones together have super hearing.

“Imagine you’re at a rock concert and trying to listen to someone talking on the other side of the room. It’s impossible. But if there’s 3,500 of you listening to the same sound, you’re going to have a far bigger chance of hearing,” Richard tells us.

These geophones are dug into the ground at 1,5-2m depth to make sure there's not much disturbance. With 3,500 listeners you’re not just going to pick up on what’s in your immediate surroundings.

“We can even pick up signals from major earthquakes on the other side of the planet. Or nuclear tests, like the one North-Korea did in 2017,” he tells us.

A massive amount of geophones conjure up a massive amount of - you guessed it - data.

A massive amount of data

- The Grane field only uses 10-20% of the data for the active analysis

- While the whole geophone zone produces a massive 2.5 TB of data - each day

- The monitoring goes all the way down to 1800 meters below the seabed.

From just an idea to approved technology

After testing the tool at the Oseberg field Sascha Bussat developed a first use report, and Sentry is now close to be an approved technology. It has already been used on the Grane field, while the Snorre, Johan Sverdrup and Johan Castberg fields are some of the potential customers.

“Through the Real Time Injection Monitoring project we’ve seen great results from working with Grane data and we’re also looking into if we can detect noise related to drilling operations. This makes me feel certain that the tool is working,” Bussat explains.

When an event is detected Sentry gives users a notification in real time and they can go into the data right away to take a look. The real time aspect and Sentry's much more user-friendly system and interface, compared to other previous monitoring solutions, are it's main advantages.

"Our aim is to let production engineers at Grane use Sentry themselves in the near future, something which would be far from possible with the systems we used previously.”

Sascha Bussat

Want to stay updated on Loop?

People

Some of the people who have been or are working with Sentry:

Mats Grønning Andersen

Richard Tøndel

Sascha Bussat

Vidar Slåtten