Responding to Covid-19

[Sharepoint] [Power BI] [HTML] [3D printing]

Here’s some of the ways our software developers and Equinor IT responded to covid-19.

There’s no denying that the current situation is a new one for all of us. Software development is a craft, requiring time and skill to get it right, but when a pandemic strikes there are new needs appearing. In order to get an overview quickly, time is really of the essence.

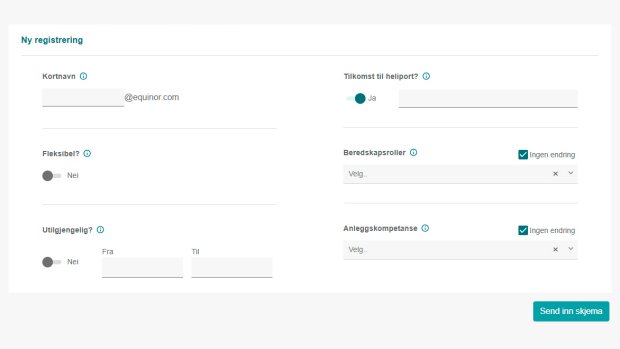

The Mobility team in Stavanger got a challenge handed to them mid-March, mere days after covid-19 lockdown safety measures were in place. Development and Production Norway (DPN) needed a status overview solution for offshore workers; where they were, if they were in quarantine and if they were able to work. The main idea is for personnel to go in and update their information themselves regularly.

“We delivered the project within two weeks and saw 3000 users the first week it was in use. It’s exciting to be working on a project that’s useful to a large group of users like this one. "

Olav Gisle Tveiten

“Development wasn’t the big challenge we faced. Most users aren’t IT-personnel, which means it has to be easy to use but at the same time we have to maintain a sufficient security level,” Olav explains.

Not their first rodeo

The team gathered all relevant data in Sharepoint, which is accessed through an API, and when users complete the form an authentication process is triggered. Once that is completed, the information layer is updated and accessible to management.

“We have a template that we use for new builds. That lets us get started quickly, and then it’s the logic we place on top of if that’s unique to the project,” developer Peder Arne Godø says.

“The challenge here was authentication, since we couldn’t rely on Azure AD or tokens. We chose SMS authentication since it was the best solution that was easily usable by everyone."

Peder Arne Godø

While they’re all used to developing at high speeds, timeframes as short as this one is a new experience, Peder explains.

“I’m used to more maturing on projects before delivering, but it’s been good so far. We’re focusing on delivering a solution now and then later seeing what we can improve when we see it in use.”

The team, like everyone else, has been working remote through the covid-19 lockdown. But that hasn’t disheartened anyone.

“We’ve had daily meetings with the client that have really helped us in being as quick and successful as we have,” Olav says.

“The solution we built has been based on what we needed here and now, but we’ll be working on improving it so we can use it for similar situations later on,” he adds.

New questions and new insight

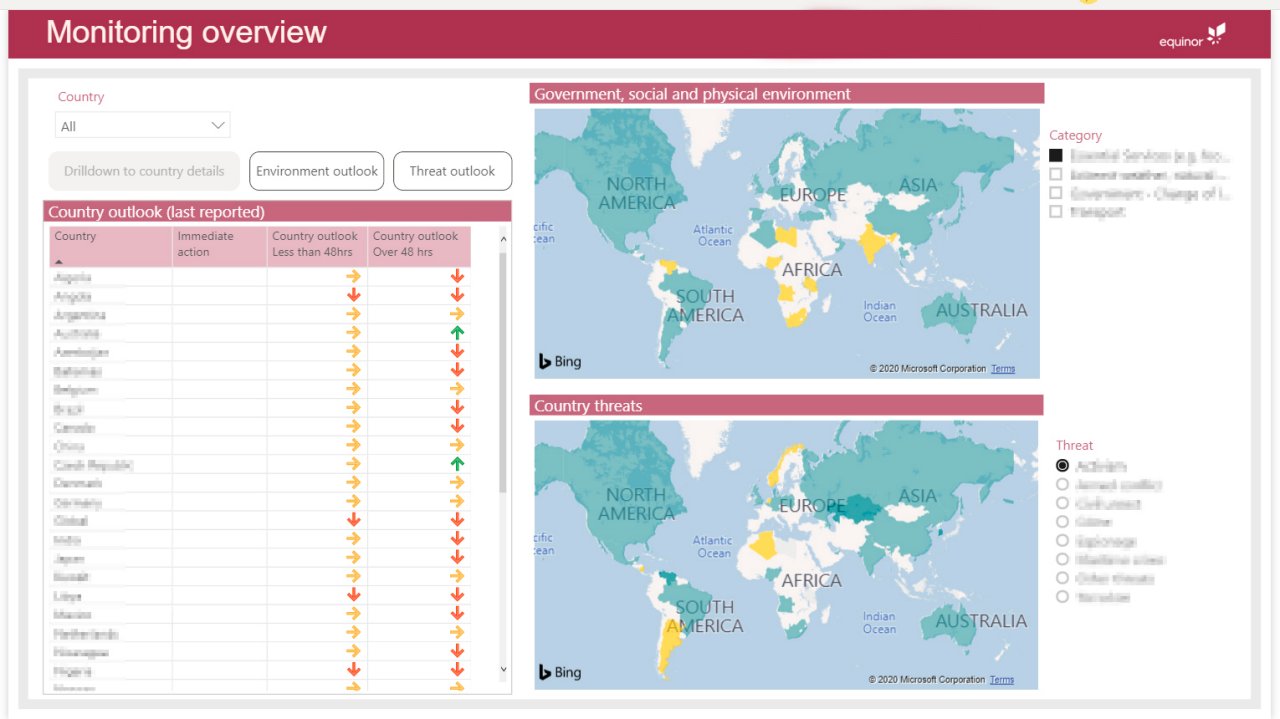

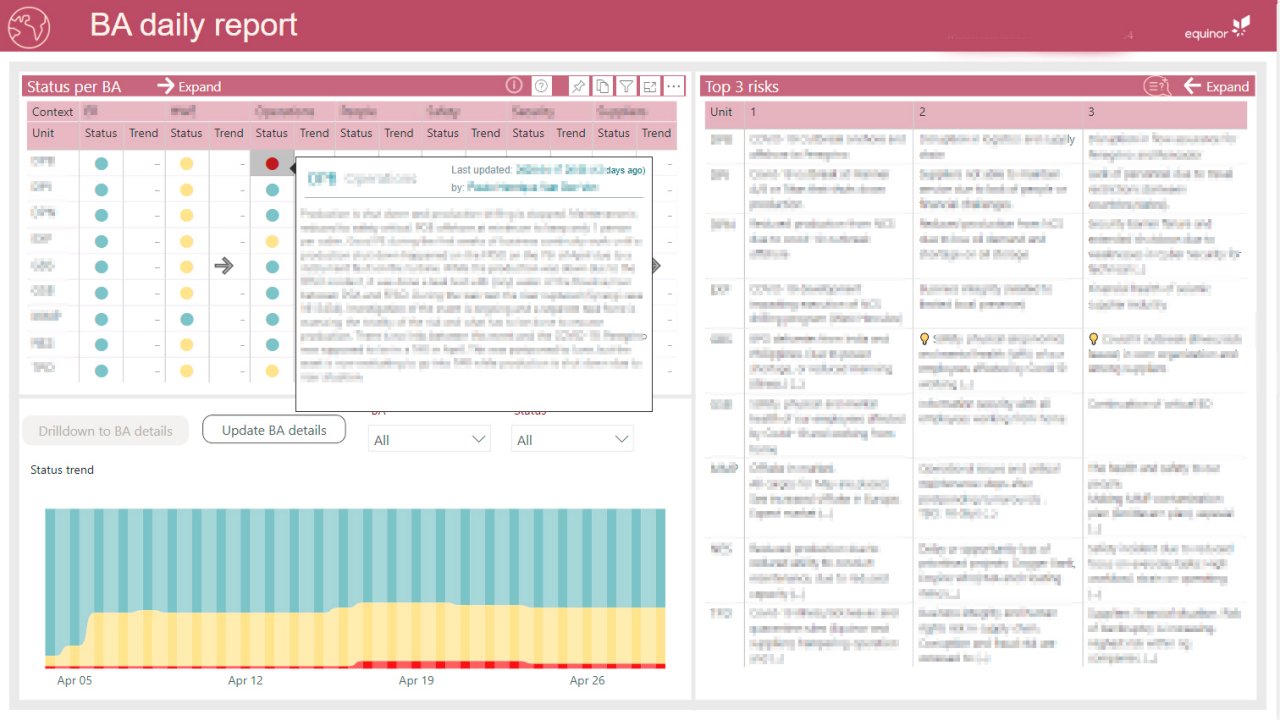

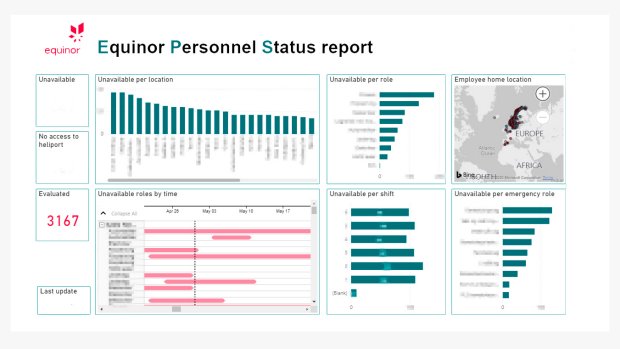

But software developers aren’t the only ones hard at work responding to the covid-19 situation in Equinor IT. Berit Reppen Lorentzen is a data visualization enthusiast and well-versed PowerBI-user. When she was contacted to help build dashboards for a covid-19 task force in need of updated data, it took her less than a week to get the first one ready.

“Both Berit and the entire team have delivered beyond expectation,” project leader Dirk Hesse tells us.

“Good visualization helps you gain insight and supports decision making. But a good dashboard also opens up for new questions that gives us new insight."

Berit Reppen Lorentzen

By mid-april, the team - which grew into 8-10 people - had delivered 6 dashboards. One displayed medical data sourced from WHO and one gave an overview of personnel status. Berit explains that the dashboards aren’t technical marvels, mostly operating on Office365, MS Forms and others.

“We’ve gone for a solution that requires different people updating different forms. And the interesting part has been seeing how they interpret and use these forms, and making sure they all fill in the same info,” she says.

Speedy visualization

Different levels of risks are displayed using the well-known red, green and yellow colors. While the dashboards are useful as singles, they’re even better coupled up.

“One dashboard lets you see risks connected to different business areas. And when you’re looking at them all together managers can easily see if other areas are struggling with the same challenges as their own,” Berit says.

She had to figure out what data to gather and display but that wasn’t the only challenge.

“I also had to do it at the same time as the task force were deciding what they needed to see. There weren’t any older tools or solutions to build on,” Berit says.

“This combined with the short time limit made for a very interesting and rewarding project,” she adds.

Contribute from home

Got a spare personal computer laying around? Then you can put it to good use, by signing up for Folding@home and turn it into a part of the largest supercomputer in the world!

- The project simulates protein dynamics

- These simulations help scientists better understand biology

- Simulations you receive are scaled for your computer

- Project was started by Stanford University in 2000

Printing protection

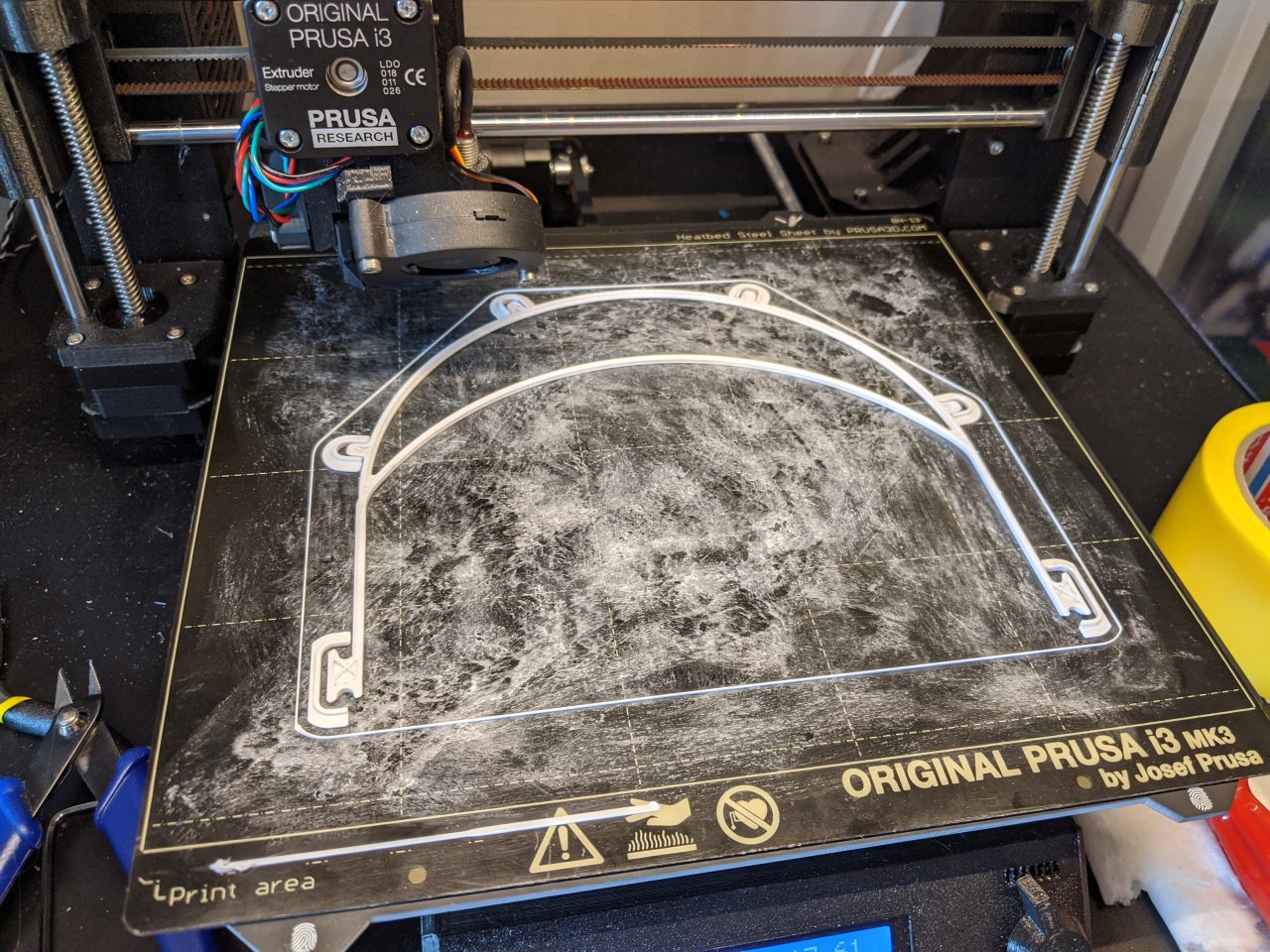

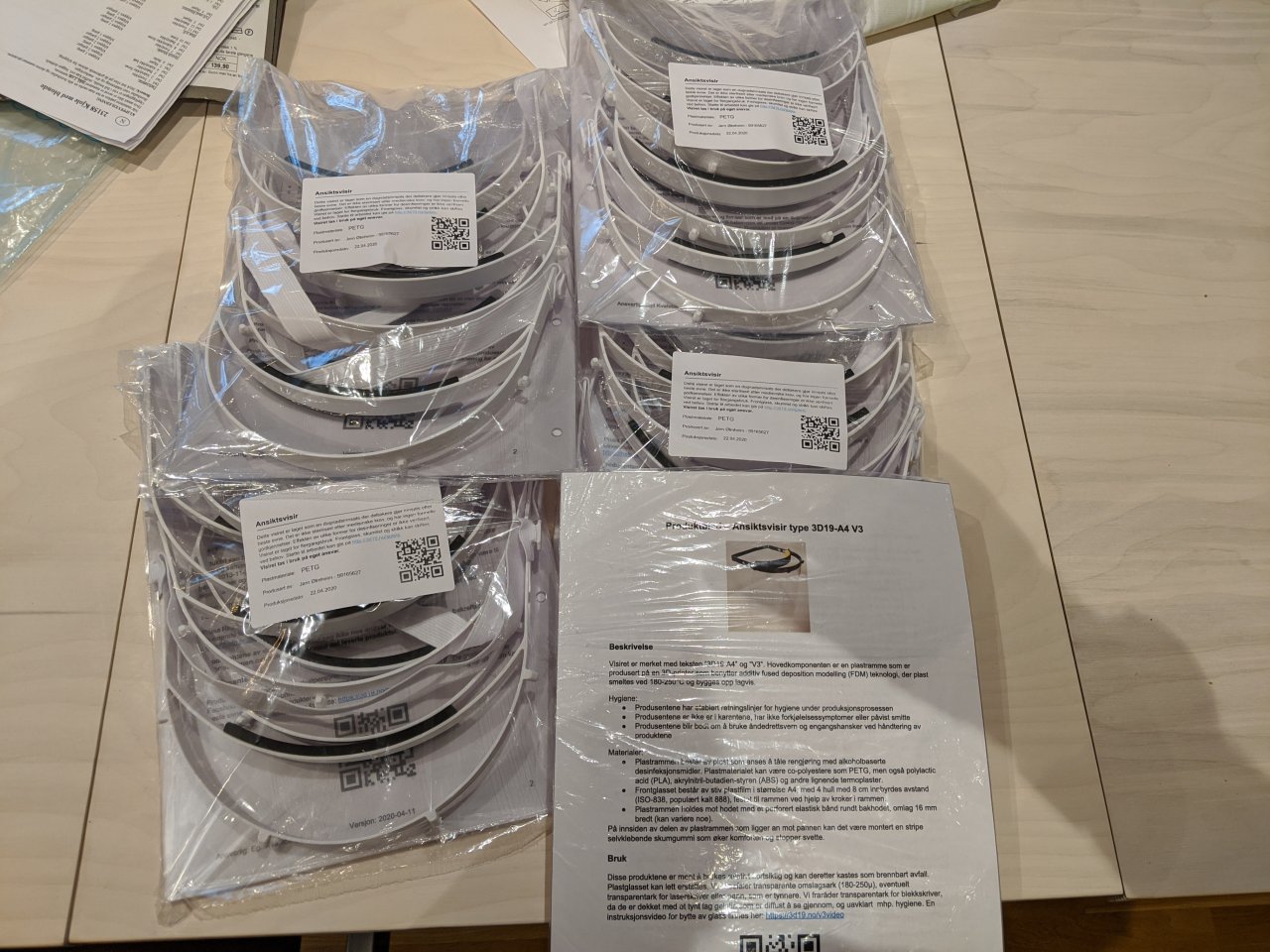

But it’s not all software and code - our people are also creating physical objects. With the pandemic, the demand for protective equipment rose. In response to that, many initiatives to 3D-print this kind of gear sprung across the world. Equinor has 19 printers, both on- and offshore, and many of our employees have been taking part.

“I figured I could do a test to see how it turned out, and it turned out great. Since my own printer is already in my home office it was easy to just turn it on and let it print while I’m working,” Jørn Ølmheim explains.

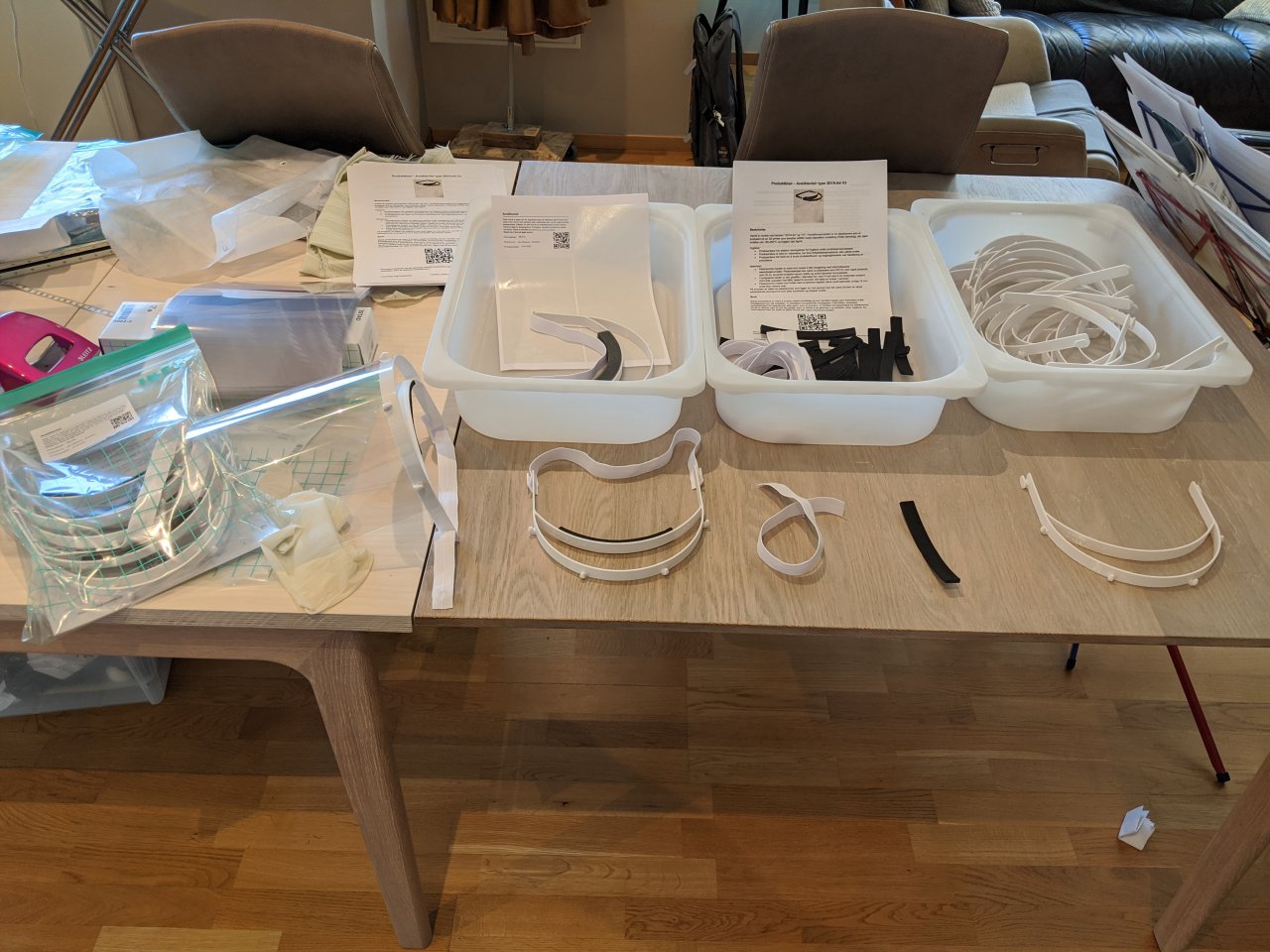

Since he started printing, he’s spent somewhere around 3 kilograms of filament creating a grand total of 140 protective visors. He’s kicked production up a notch and even has an assembly line.

“There was a local retirement home here in Trondheim that sent in an order and I saw I had that number of visors available. So I packed them and went for a run down to deliver them the same day. They were incredibly grateful for the gear,” Jørn says.

“3D printing is a simple but great way to help in fighting the pandemic, in addition to staying home."

Jørn Ølmheim

3D19.no

- An initiative to 3D print free protective equipment for Norwegian healthcare providers

- 3600 participants

- 35 000+ protective visors printed and delivered

- Similar initiatives are found in a variety of countries

Ahead of the curve

Equinor’s own printers are also part of our initiative to establish procedures to help us print spare parts, should the supply chain be disturbed by the pandemic. And the ones on land are, like Jørn’s, printing protective gear for local health care providers. Our printers offshore are hard at work printing the same gear for our sick bays on our platforms.

“This is really an exercise in distributed production. And a great example of how when something needs to be done quickly and suddenly, there are many people ready to help out.”

Hallgeir Holien.

He’s one of our developers, who’s private 3D printer is also hard at work printing in his home office. Like Jørn, he’s also printed and assembled the entire visor, but you can always participate by just printing certain parts. The Norwegian postal service, Posten, also covers shipping costs for the entire “Makers against covid-19”-project.

If you have a 3D printer at home, why not consider joining a maker community? And if you’re lacking things to read, then we have a library of stories for you right here at Loop. Some of them you’ll find just below.

Until next time, stay safe and take care!